Questions & Answers:

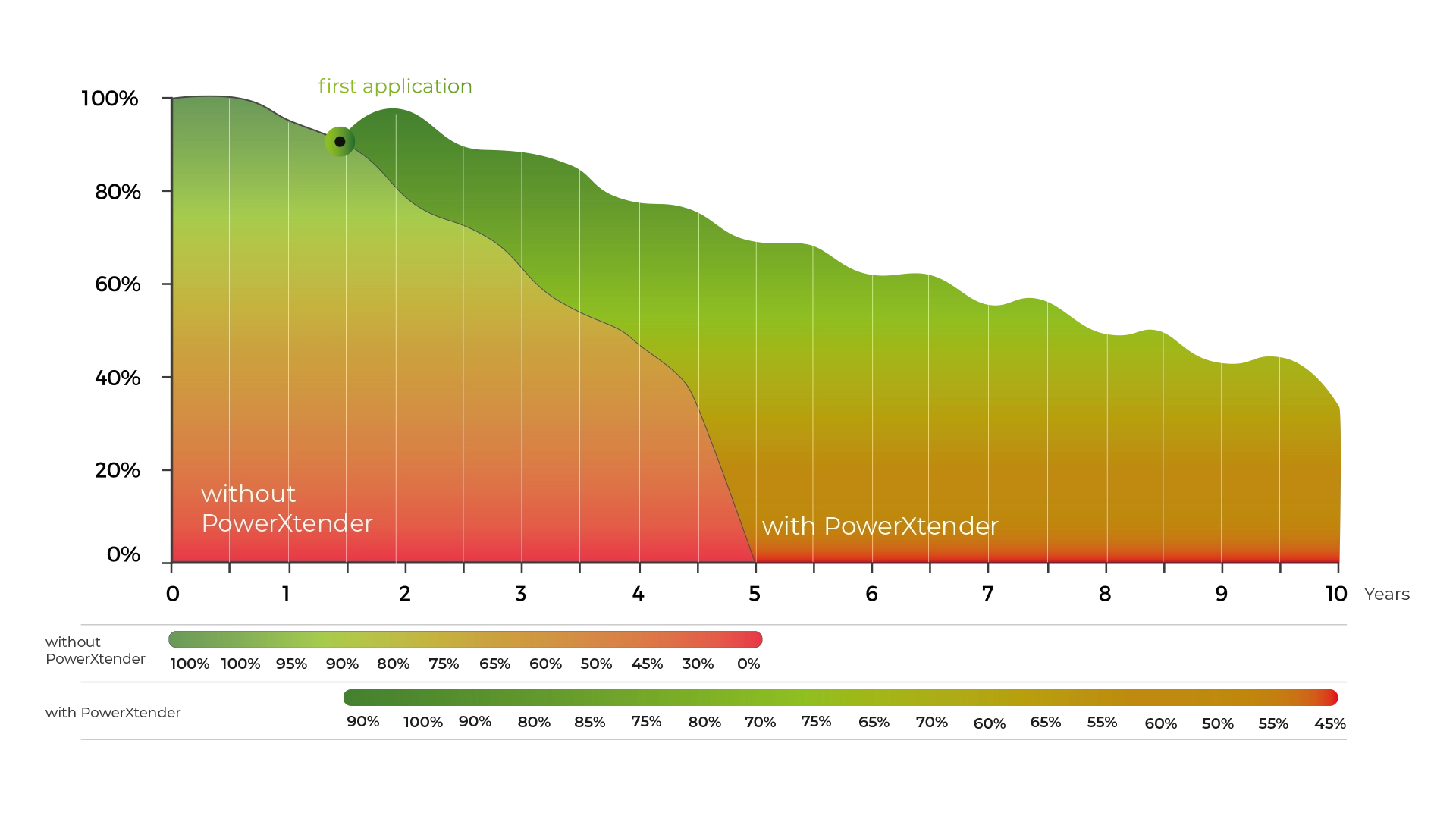

PowerXtender is intended to keep the accumulator in a working condition and prolong its life. To save clients time, finances connected to service and new replacement of accumulators.

PowerXtender is intended for common lead-acid accumulators with sulphuric acid electrolyte.

PowerXtender is designed as a preventive/maintenance additive for working accumulators. However; it is sometimes possible to bring completely dead accumulators back to operation, if the accumulator is otherwise in good condition. If accumulators (lead plates) are cracked or degraded too far, there is nothing that can be done to save it

PowerXtender application is recommended every 6 to 12 month depending on intensity of accumulator use.

NO. If applyed correctly, it does not damage the accumulator. See table of dosage.

We do not recommend to apply PowerXtender into a FULLY CHARGED accumulater as a strong chemical reaction will occur (foam comming out of cells)

PowerXtender disolves the sulphate from plates which causes the overheating during charging process as the accumulator has high inner resistance, which will be lowered and the accumulator will not overheat.

Yes, the accumulators capacity is determined by its weakest cell.

The best way is to wait few weeks till the level of electrolytes drops and apply the recommended volume then. If you can apply min ½ of the volume go ahead and apply it and apply the second ½ by the next service interval when applying distilled water. Caution: DO NOT TAKE OUT THE ELECTROLYTE out of cells as the result may not be as expected. The PowerXtender is a additive which needs the original electrolyte to work properly.

a lot of foam is formed, it is a definate indication that the process is working, but you need to slow down the application to each cell – apply in 4 stages. Use a suitable material to carefully remove the escaped solution and dispose of it in accordance with the manufacturer’s instructions for working with sulphuric acid.

No worries. Warming of the accumulator during PowerXtender application is a result of the chemical reaction, cleaning and reconditioning.

During the chemical process the sulfate is diluted and gravity of sulfuric acid will be lowered and therefore it is necessary to charge the accumulator with a standard chagred within 24 hrs after the reaction is finished.

Charge the accumulator with a standard charger. The PowerXtender needs about 20 charge cylces during which the capacity will be going up. After the increased capacity will be stable.

After PowerXtender applicatio, we do not recommend letting the accumulator sit unused. If you